CDL (Center diff lock) Sensor/Switch for 80 series TLC

After finding that the CDL light wasn't coming on I figured it was time for some detective work.

With the ignition key turned to the Start position (engine not running), you can press the CDL switch and listen for the actuator on the transfer case to cycle (a second or so electric motor sound). I could hear the motor cycle so that meant that it was most likely the CDL Sensor/Switch malfunctioning.

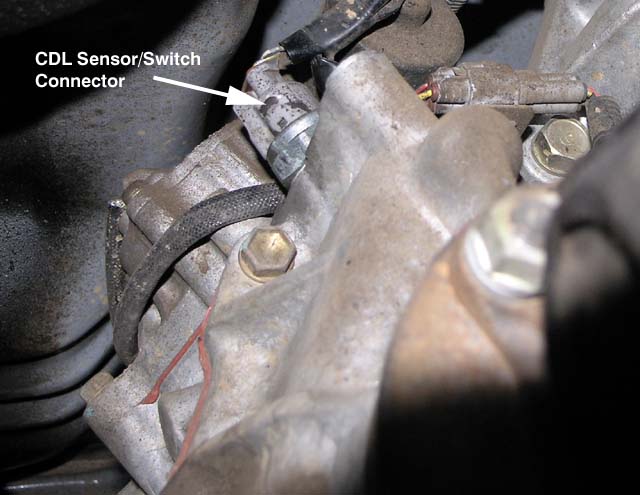

FIrst step is to remove the Sensor/Switch from the transfer case. You can access it from under the USPS and there's just enough room to fit a spanner on it (hex head) and 27mm. Remove the connector to the harness first and move it out of the way. The following picture shows the CDL Sensor/Switch - don't mistake it for another connector, there are several in the same general area.

And next a zoom in of the Sensor/switch. There's a tab on the side of the connector that you squeeze to be able to pull the connector off the Sensor/switch. Standard right hand thread on the Sensor - so just turn anticlockwise to remove. It's not on too tight but will probably need a strike on the spanner end to break it loose.

The next picture shows the actual Sensor/switch after removal from the vehicle. On measuring the contact resistance at the connector it was open circuit even when the ball end was pressed in. Basically all the Sensor is is just a switch, open circuit when out, closed circuit when pressed in. I figured it was highly unlikely that the Sensor was actually broken, more likely the contacts had just glazed over. I have found that many switch contacts can fail when insufficient current flows which would be likely in this case since the switch action is just a status input to the ECU.

So, my first (cro-magnon) attempt at 'repairing' the switch was to strike it a quick blow with the spanner end with the Sensor laying flat on my vise. A couple of strikes on the flat sice and the meter now showed continuity when the ball end was pressed in. Neat, installed back into the 80 and it all seemed good (read on...)

A couple of days go by and I test the CDL switch every so often but find it didn't always light up on the dash. So, removed it again and this time checked the resistance carefully as I cycled the ball end in and out. It acted like a 'dirty' switch, i.e. the resistance waivered around as the switch was slowly pressed in. So, I figured that if the contacts were still 'dirty' it would be a good idea to run some current through the switch as it cycled. I have a bench supply (for my electronics work) and set it to around 200mA current limit and 12V. I applied this across the contacts of the switch (off the vehicle of course) and pressed the ball end in slowly and cycled it a 20 - 30 times. Hooked the meter up again and now it was 0 ohms through the entire stroke of the ball end - no waivering around - SOLID. Back onto the vehicle and after 7+ years (fixed 2005) it has been solid and fully operational. Update, 2016 and it failed again, used 24V and 300mA current limit to 'clean' the contacts again and all operational. 12V wouldn't start the cleaning cycle this time.

This is a reasonably common problem with switches that are designed for higher current use. The contacts rely on the higher currents to 'clean' the contacts. It would appear that the CDL switch falls into this category, but since it is being used as a sensor in this application, the currents are likely very small and unable to 'clean' the contacts.

So, before you rush out to buy a new Sensor/switch, consider trying this 'repair'. You could more than likely use a (couple of series) 9V battery to do the 'cleaning' since it won't be able to supply currents high enough to damage the switch contacts, but should be able to provide a few hundred milliamps in a short circuit like would be needed for the 'cleaning' cycle.

A picture of the connector end of the CDL Sensor/switch. Don't lose the aluminium washer when you remove and reinstall it.

.

.